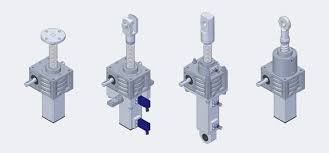

Trapezoidal lifting screws are the unsung heroes of the industrial world, silently powering a vast array of linear motion applications. These robust and cost-effective actuators convert rotary motion into powerful lifting or pushing forces, making them ideal for diverse tasks requiring precise control.

Understanding the Trapezoidal Thread:

The key element of a trapezoidal lifting screw is its namesake – the trapezoidal thread. Unlike the smoother Acme thread, the trapezoidal thread has a flat top and bottom, creating a higher friction surface. This characteristic offers several advantages:

- Self-Locking Ability: The geometry of the trapezoidal thread allows for self-locking, meaning the screw jack can maintain position without an additional brake when not in motion. This simplifies system design and reduces costs.

- Higher Load Capacity: Compared to ball screw jacks, trapezoidal screws can handle significantly higher loads due to the increased surface area for friction. This makes them suitable for heavy-duty lifting applications.

Applications for Trapezoidal Lifting Screws:

Trapezoidal lifting screws find application in a wide range of industries, including:

- Manufacturing: Used for material handling, machine adjustments, press applications, and mold clamping.

- Construction: Employed for lifting platforms, scaffolding adjustments, and formwork positioning.

- Energy: Play a role in wind turbine blade adjustments and solar panel positioning systems.

- Transportation: Utilized for access ramp adjustments and vehicle loading platforms.

For more information on screw jack design and material selection, you can visit MechJacks https://mechjacks.com/en/. MechJacks is a leading manufacturer of high-quality screw jacks, offering a wide range of options to suit various industrial applications.

Advantages of Trapezoidal Lifting Screws:

- Cost-Effective: Trapezoidal screws offer a simpler design compared to ball screw jacks, making them a more budget-friendly option for many applications.

- Reliable and Durable: The robust construction of trapezoidal screws ensures long-lasting performance in harsh industrial environments.

- High Load Capacity: They can handle substantial loads, making them suitable for heavy-duty tasks.

- Self-Locking Ability: Eliminates the need for additional brakes in certain applications.

- Simple Maintenance: Trapezoidal screws require minimal maintenance due to their straightforward design.

Considerations When Using Trapezoidal Lifting Screws:

- Lower Speed and Precision: Compared to ball screw jacks, trapezoidal screws have higher friction, resulting in slower operation and slightly less precise movement.

- Heat Generation: High friction can lead to heat generation during extended operation. Ensure proper lubrication and consider duty cycle limitations.

Conclusion:

Trapezoidal lifting screws are reliable and cost-effective workhorses for linear motion tasks. Their self-locking ability, high load capacity, and simple design make them a popular choice across various industries. While they may not offer the high speeds and precision of ball screw jacks, their versatility and affordability make them a valuable asset for numerous applications.